Production Line Accessories

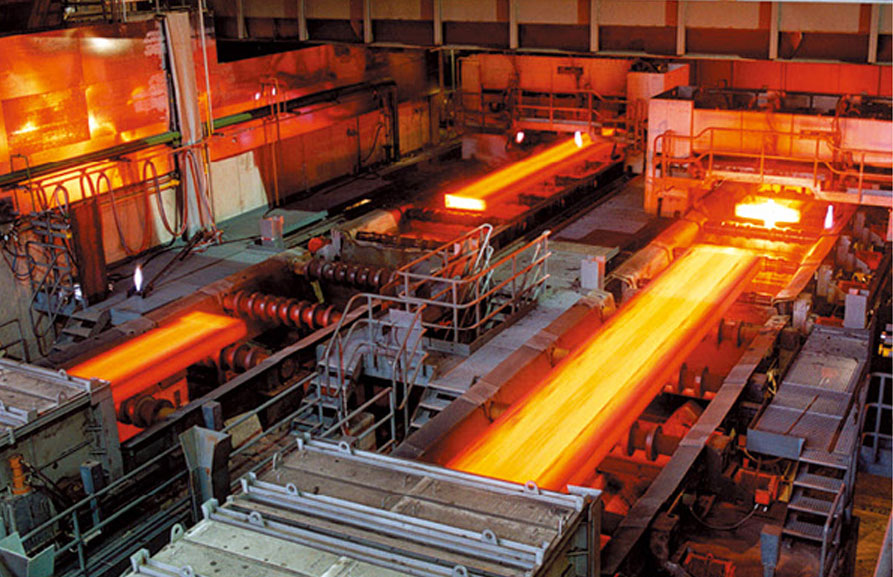

Rolls for steel sheet

The working principle of the steel plate mill is to press the steel plate thin and form a strip of the required width and thickness by the rotating pressure of the rolls. Specifically, the steel plate is fed into the roll gap in the mill, and under the rotating pressure of the rolls, the steel plate is continuously rolled thin, and the thickness and shape of the strip are controlled by adjusting the rotating direction and speed of the rolls.

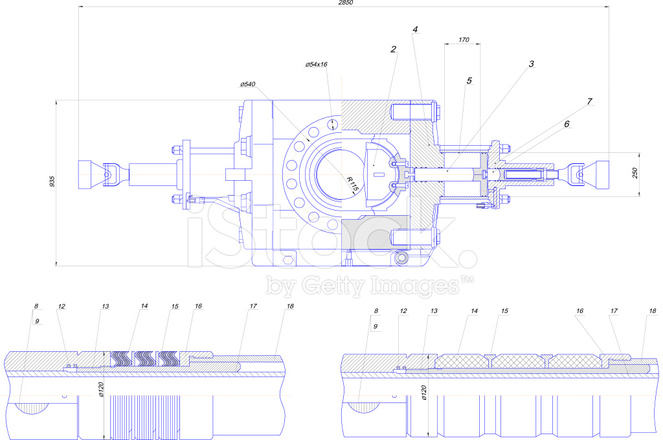

According to the number of rollers can be divided into two, four, six, eight, twelve, eighteen, etc.; according to the arrangement of the rollers can be divided into “L” type, “T” type, “F” type, “Z” type and “S” type. type, “Z” type and “S” type. Ordinary rolling mill mainly consists of rollers, racks, roller distance adjustment device, roller temperature adjustment device, transmission device, lubrication system, control system and roll removal device and so on. Precision calender is based on the increase of the device to ensure the calendering precision.

Our Process